Finding the motivation to work up a real sweat, whether that’s going for a morning run or an after-work gym session, can be tough at this time of year when it’s still dark most of the day. The good news is that spring is just around the corner and you can start that season in better shape if you treat yourself to some new workout kit right now. Why? Wearing new exercise clothing can give you the added willpower you need to start moving, and simply putting on your fresh clobber gets you in the right frame of mind for exercise and increases the chances of you training that day, according to research from Northwestern University in the US. So treat yourself to a new top and shorts or leggings – bright colours are good, especially if you’ll be running outside – and put them on first thing Saturday morning to boost your chances of increasing your activity levels.

Author: admin

Reignite your spark

What’s the biggest obstacle blocking your path to a fitter, healthier and happier life? For many of us, at least some of the time, a shortage of motivation to make small but significant changes to our daily routine keeps us stuck in a vicious circle.

A friend explained his lapsed gym membership to me like this: every morning he wakes up with ten Enthusiasm and Motivation Units (EMUs). He’ll lose one EMU on his commute, a couple more during meetings, one in the queue for lunch and so on every time his patience is tested. He only ever gets to the gym after work if he has at least one EMU left. If not, the only bar he’s going near is his local.

His motivation model makes a lot of sense – we all wish we could instantly summon up extra EMUs when we need them. Like when we know we should go to the gym or for a run (because we always feel amazing afterwards) but going straight home or to the pub requires far less effort. Now, thanks to our guide to maximising your motivation levels with minimal effort (p56), you’ll be able to make the right call every time and build a stronger, leaner and healthier body. So I’ll see you at the bar. You know which one.

new not English sound

new not English sound

REG 2 CAT MAN

REG 2 CAT MAN

REG1 CAT DAT

REG1 CAT DAT

H new REG

H new REG

303

303

Jordan 195

F1 RESTORATION

I don’t quite yet have a fully rebuilt and dyno-tested engine, but the good news is that the Peugeot internals have passed crack testing and there are, so far, no horrible surprises. I’m still itching to see — and hear — it up and running. I have never been in a dyno room with a V10 Formula 1 engine on full song. People who have tell me it’s one part awesome and one and a half parts terrifying.

In the meantime, we have started to put the final touches to the chassis build of my ex-Rubens Barrichello Jordan 195. The first job was fitting the fuel tank. The physical fitting is not a simple job, because the aperture through which it must pass to fit inside the monocoque is very small. All the foam inside must be removed then painstakingly refitted into the tank, along with the pump hardware. This means the guys at Tour-de-Force Power Engineering are essentially working blind most of the time.

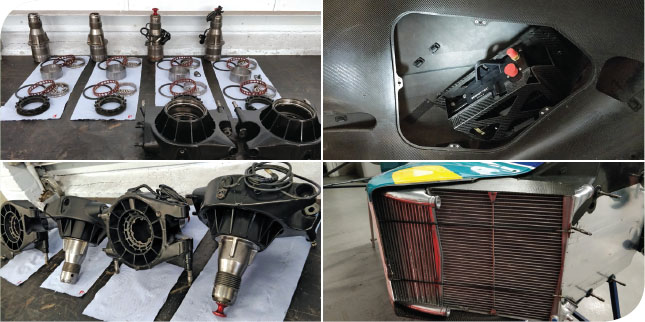

The uprights have been stripped, crack-tested and rebuilt. Visually they appeared to look fine and non-destructive testing proved this to be the case. It’s only when they are apart that one can appreciate just how much design and manufacturing skill has gone into these components. The uprights on the car are fabricated from titanium with a machined centre. They are beautifully made.

I have been incredibly lucky to find another pair of front uprights to use as spares, but interestingly these are fabricated from steel. I can only guess that these were possibly off a test car. Before rebuilding the uprights, we re-greased the bearings, which themselves were in such good condition that they did not need replacing.

The radiators have also now been serviced. They were sent to an F1 radiator specialist at Silverstone to be ultrasonically cleaned and pressure tested. Apart from a minor repair needed to one small part of one radiator, everything else was perfect and they have now been mounted back on the car with fresh fittings and fasteners.

The Brembo brake callipers were in great condition and have been stripped, cleaned and rebuilt with new seals and fittings. Suitable carbon-carbon discs and pads were sourced. Carbon-carbon is an incredible material, but the braking system used in 1995 was relatively simple, certainly compared with the brake-by-wire and energy recovery systems of modern F1 cars.

The modern electronics have been mounted in the original box locations on the car, including the ECU above the fuel cell. New brackets were produced for the mounts in the tub and all components fit into the original recesses with the period closing panels. We can now move on and begin to build the wiring loom. We are also testing the original dash and cockpit electronics to ensure these are fit for purpose.

New front and rear dampers are being manufactured and should be on the car very soon. Engine permitting, we aim to give the car its shakedown test in the early spring at Snetterton, and I am hopeful that it may get one of its first public outings at the Goodwood Festival of Speed in July, followed by some demo runs at Brands Hatch in August and Jarama later in the summer.

Next month: final pre-testpreparations – and will Warren’s ears be ringing?

Thanks to: Tour-de-ForcePower Engineering, Bedford; Engine Developments, Rugby

Alfasud Sprint Veloce

RACER REBUILD

GARAGISTA

THIS MONTH ALFASUD SPRINT VELOCE MAKES FIRST PUBLIC APPEARANCE • JORDAN 195 REBUILD LATEST • MGB STRIPDOWN HIGHLIGHTS BAD NEWS

It was, I suppose, a slightly surreal feeling. The Alfa has been edging ever closer to completion over the past few months and I’ve followed progress every step of the way, but so many people have invested so much time in the project that I found it quite hard to believe the finished article was actually mine. I guess it will eventually sink in.

I’m thrilled to bits with the way it looks. Raceworks did a stunning job with my Giulietta – and the ’Sud looks every bit as good. I’m really not sure there’s anything they could have done to improve it and I can’t wait to try it for the first time. If all goes to plan it will have turned a wheel by the time you read this, most probably at Donington Park, and we’re hoping to get in a couple of sessions before heading off for the car’s debut race at Barcelona in early April. I’m still hoping Dickie Meaden will be able to share it with me at some meetings, though he is also committed to driving Gérard Lopez’s Ford Capri. When Dickie isn’t available, I guess I’ll probably race solo. The programme for the year is now pretty settled: Peter Auto’s Heritage Touring Cup, plus the Donington Historic Festival in May and July’s Silverstone Classic.

It was a busy event and there were presentations to several well-known former Alfa drivers, including Carlo Facetti, while Gianluigi Picchi was also present. He was prominent in the European Touring Car Championship during the early 1970s: in 1971 he won his class in a 1300 GTA Junior and finished second overall to Capri driver Dieter Glemser.

I’ve always known that Alfa really treasured its racing past – and this confirmed it. I travelled to Milan with long-time Alfa Romeo aficionado Jon Dooley, who used to contest the British Saloon Car Championship in ’Suds and GTV6s. Jon has been a great help in terms of researching the Alfasud Sprint’s Gp2 racing history – and stayed on in Milan after I had left, to meet the Albertinazzi family at EPA Power. Giovanni Albertinazzi built, prepared and raced Gp2 Sprints in both 1.3- and 1.5-litre form back in the day, so we are gradually building up a portfolio of valuable information.

Next month: first impressions from behind the wheel

Thanks to: Raceworks, Characters Signs, DC Electronics

We’ve applied for the Alfa’s historic technical passport (HTP) – ours is the first Gp2 ’Sud Sprint Veloce to have been prepared in modern times – FIA inspector Jim Lowry is on the case and, as planned, I’ve booked a couple of one-to-one coaching sessions with John Norrington. My only previous front-wheel-drive experience has been on the public road, so I’m aware that I have a bit of learning to do…

HISTORIC RACER

MGB Roadster

A few tweaks are in train for the new season – such as new brakes and a rebuilt gearbox. Oh, and the heavy bit up front. Nick Trott takes up the story…

Ithink we’re going to be late for the season openers. We were hoping to get on the grid for the Equipe GTS trackday at Goodwood on March 5, then the season opener at Silverstone on the 7th, but we’ve found a few other issues with the MGB that need sorting. One of them is quite a big, heavy issue…

Firstly the good news. The gearbox, traditionally a weak point on MGBs, is rebuilt. It’s easy to destroy the innards with imprecise heel-and-toeing and/or rushing the shifts, and small issues seem to turn into big problems quite quickly. As an MGB driver, you have to remember that in the rush and fury of racing slow is best when shifting cogs – its counter-intuitive but absolutely crucial. We plan to keep the ’box in tip-top condition throughout the season, and into 2019 hopefully, and avoid a mid-season rebuild like last year.

The suspension and brakes are also fitted – two areas that we believe were weak points last year. We’re hoping for better performance and stability all round, with fewer ‘bad habits’. For instance the B was always one of the more, um, sideways cars on the grid but despite the its crowd-pleasing antics we’d really rather it wasn’t quite so drifty.

Roll oversteer was the key problem throughout 2017, and we’re hoping to have this cured with new parabolic leaf springs and general set up changes. Less entertaining for the spectator (and drivers) but faster, we hope.

Finally, the big heavy issue. With the cylinder head removed an inspection of the bores revealed a rather tired block. A new one isn’t criminally expensive, which is the case for pretty much everything on the MGB to be honest, so owner Ed has ordered a new block.

So yes, we’ll be late for the first races of 2018 – but it’ll be worth the wait. BRX 855B will be fitter and faster than ever. Probably about time its drivers were too…

Next month: Removing the dents, tidying up the shell in preparation for the bodywork rebuild.

Thanks to: Roy Gillingham of

www.chequeredflagclassics.co.uk

Once painting and assembly were complete, and the final graphics had been applied, the Sprint made its public debut at the London Classic Car Show, in mid-February at ExCeL, and immediately received some very positive feedback via social media. I wasn’t able to attend the show myself, but had a very worthwhile excuse – a clashing fixture in Italy.

I’d been invited to the annual Scuderia del Portello ceremony at the Museo Storico Alfa Romeo, which forms part of the site where the marque’s old Arese factory once stood, in Milan. We were up for an award for our team’s performance with the Giulietta Ti at the 2017 Goodwood Revival, when Dickie Meaden and Steve Soper finished second on aggregate in the St Mary’s Trophy. It was great to get such recognition for our efforts with historic Alfas – a real honour, especially in such distinguished company.

SPEEDSHOP

TOP STORY

BUYING • SELLING • AUCTIONS • RACE & ROAD CAR PROFILES

Double-barrelled diehard

Muscular British classic that scored competition successes galore

Big Healey – sounds like a character in a gangster film, no? Someone brawny, tough, determined. And there’s a lot in that. Donald Healey’s co-production with the far larger Austin company, under its BMC umbrella, resulted in a sports car with just those qualities, as proved in major rallies and plenty of racing. A car boasting period credentials in those events has become much coveted, but with heading for 60,000 Austin-Healeys built in several variants, they offer plenty of choice for the enthusiast buyer. The car Vintage & Prestige has in stock, in the desirable BN6 spec, did its bit for Britain’s ‘export or die’ campaign – built at MG’s Abingdon works in 1958 with left-hand drive, it went straight to San Francisco and put treasured dollars into the home economy.

After 32 years the car returned to a home in Jersey and has recently had a complete restoration to concours standard, with just about everything checked, reconditioned or if necessary replaced (including valves and valve seats to utilise unleaded fuel). Casual onlookers may easily miss the differences and assume it’s a Healey 3000, but this earlier model is a 100/6 – pretty similar but lacking 400 of the ccs in its big brother’s title. Whereas the first Austin-Healeys made the most of a four-cylinder Austin A90 engine, the 100/6 upgraded to a big six from the Westminster saloon and, although it was hardly sophisticated, the new 2.6-litre pushrod engine was sturdy and simple to fix. Unshackled from the weighty Westminster it brought enough horsepower to make the Healey lively on the road. In truth the extra weight of the six cancelled out its power until, in 1958, a new 12-port head and manifold raised the figure from 102 to 117bhp. That’s the spec of this BN6 model, the final iteration before the bigger-engined 3000 arrived.

Healey redesigned his car to swallow the longer six-cylinder engine, increasing the length by six inches and making an already attractive design even better proportioned, especially with the sweeping two-tone paint option in classic ice blue over white. At first you could have a couple of cramped perches in the rear, but that wasn’t popular and disappeared with the arrival of the BN6.

With its drum brakes and ladder chassis the 100/6 offered no technical innovation; Healey very sensibly chose simple, affordable parts from the generally uninspiring Austin range, relying on weight loss and million-dollar looks for sales appeal. Sports cars famously generate low volumes and similar profit margins, but are essential to chrome-plating your market image, which is why BMC’s Leonard Lord pounced on the single example the Healey company built and showed at the 1952 British Motor Show. He needed a ‘halo car’ and here was one ready-made, using parts from his range. Overnight he made a deal with Healey, the car’s name became double-barrelled and Healey’s firm went from turning out hand-built vehicles to being a maker recognised across Europe and America. In 3000 MkI and II form the Big Healey would survive until 1968, but the car’s extrovert character and its huge competition success ensures that in all its versions it remains a favourite from Britain’s golden era of sports cars.